Using 4G LTE Cellular for Remote Out-of-Band Access

Using 4G LTE Cellular for Remote Out-of-Band Access

In any application that requires communication with remote network elements, a secure, reliable means for out-of-band access to the remote network can often spell the difference between success and failure. An out-of-band management solution is an important part of any network management application, but in situations that require communication with distant, difficult to reach network elements, a workable out-of-band management solution is absolutely critical.

When your primary means of communication with a remote network suddenly fails, a back-up, out-of-band management solution can provide an alternative means to communicate with devices on the remote network in order to restore communication capabilities, reboot nonresponsive devices and tweak configuration parameters. In localized network applications, out-of-band management solutions can be comparatively simple; dial-up modems or hard wired redundant networks can usually get the job done. But in cases that involve communication with network devices at extremely remote locations, a more advanced approach to out-of-band management is often called for.

In remote network management applications, satellite internet or cellular broadband are most often called upon to fulfill out-of-band communication needs. While satellite internet generally provides a wider coverage range, cellular broadband networks are often more economical and mobile and are typically more reliable than satellite under inclement weather conditions. Although out-of-band access via satellite will be discussed in a future white paper, this article will focus primarily on the use of a 3G or 4G LTE cellular network to provide out-of-band access.

Cellular broadband based out-of-band management solutions can be applied to a wide variety of different types of remote network management applications. Cell based out-of-band communication lends itself particularly well to almost any remote network application that includes network equipment located in distant, hard-to-reach locations where connection via dial-up, land-line is either impractical or impossible. Although cellular broadband is used in literally hundreds of different out-of-band management applications, this article will discuss five popular applications that demonstrate the advantages and capabilities of a 4G LTE cellular broadband-based out-of-band management solution.

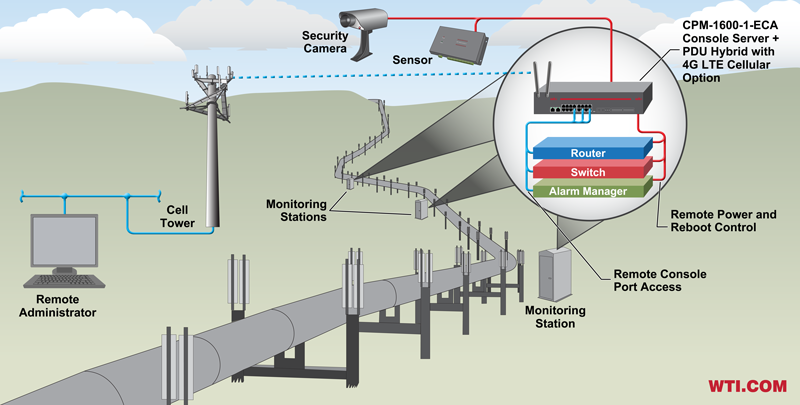

Managing Network Devices at Remote Pipeline Monitoring Stations

In the petroleum industry and in civic infrastructure, large industrial pipelines essentially serve as the circulatory system of the industry. If this circulatory system fails or shuts down, then often the corporate endeavor that it serves also fails; just as we humans fail when our circulatory system shuts down.

It doesn’t matter if the pipeline is carrying drinking water or crude oil; large commercial pipelines require constant monitoring and maintenance to ensure structural integrity and pipeline security. In order to make certain that pipelines are mechanically sound and free of potential problems, monitoring stations are typically installed at regular intervals in the pipeline to check conditions such as pipeline pressure, leakage, developing corrosion, unacceptably high or low temperatures and other factors. In many pipeline applications, these monitoring stations will also include security devices such as CCTV, sensors and other security monitoring apparatus to help guard the pipeline from unauthorized intruders.

In most cases, the sensors and security equipment at each pipeline monitoring station are linked to a central control facility using an Ethernet LAN backbone (typically a hard cable connection or satellite network.) This allows administrators at the control facility to easily monitor pipeline conditions at hundreds of separate pipeline monitoring stations and effectively dispatch tech teams to address any problems that might arise.

This works well under ideal conditions, but if the primary in-band connection fails or if inclement weather makes satellite communication unviable, then a 4G LTE cellular broadband network often provides the only workable alternative for back-up, out-of-band communication with remote pipeline monitoring stations.

In this case, remote administrators and IT support personnel can connect to the network at the remote pipeline monitoring station via cellular broadband in order to restore communication with the primary network using tools such as a serial console server or switched PDU installed at the monitoring station. Since rack space is often fairly cramped at these remote monitoring stations, a hybrid device, such as a CPM-1600-1-ECA Console Server + PDU Combo with WTI's 4G LTE Cellular Option can provide the ideal solution, by allowing both access to console port functions on remote devices, plus remote control of power switching and reboot functions. In pipeline monitoring applications that rely on DC power, a WTI RPC Remote DC Power Switch and DSM-40DC-E Serial Console Server with WTI's 4G LTE Cellular Option can be employed to provide out-of-band management capabilities.

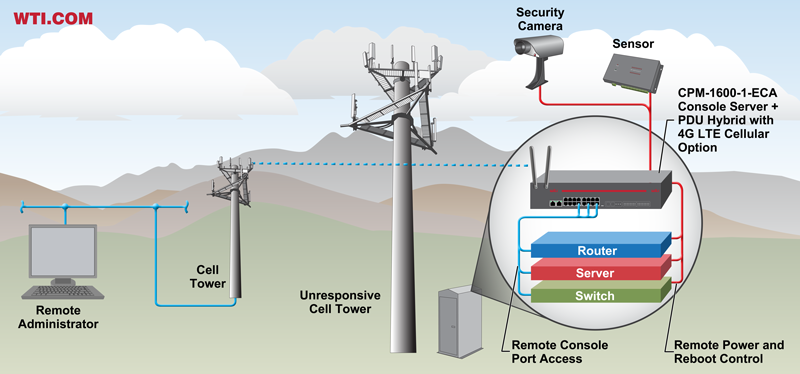

Managing Network Devices in Cell Towers

In addition to cellular antennas and signal boosters, most cell towers also include networked sensors, security cameras, power gauges and other devices that are used to monitor conditions at the remote cell tower without a constant, on-site human presence. Typically, sensors and other devices are connected to network elements such as switches and linked to a central Ethernet LAN backbone. This allows administrators at distant management facilities to track power conditions, service outages and environmental factors at the cell tower site, plus enables access to cameras and motion detectors at the remote site that are used to verify security.

It’s fairly obvious that the primary means of communication with the cell tower will most likely be cellular. However, in the event that the tower goes dark and direct cellular communication with the tower itself is not possible, a secondary, out-of-band means of communication with the remote tower is absolutely vital in order to restore the tower to normal operation without a costly service call or extensive down-time.

Due to the remote nature of many cell tower sites, a 4G LTE cellular broadband connection often provides the most practical means for out-of-band communication without the need for a hands-on service call. In this case, a CPM-1600-1-ECA Console Server + PDU Hybrid unit with the 4G LTE Cellular Option can be installed on site to allow administrators to communicate with devices at a dead cell tower via the nearest functioning cell tower.

In AC powered applications, a CPM-1600-1-ECA Console Server + PDU Hybrid with the 4G LTE Cellular Option can be used to provide out-of-band access to console port command functions and control power switching and reboot functions at the remote site in order to bring the tower back to life again. In DC powered cell tower management applications, a WTI RPC Series Remote DC Power Switch and DSM-40DC-E Serial Console Switch with the 4G LTE Cellular Option can provide out-of-band cellular broadband access to console port command functions and power switching and reboot capabilities.

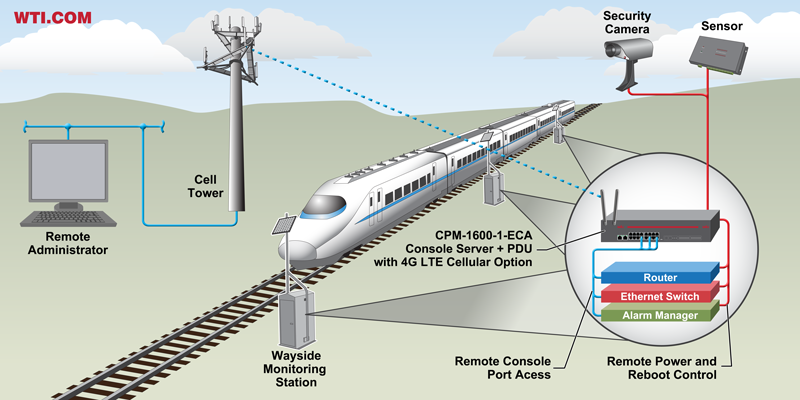

Managing Network Devices in Wayside Railroad Applications

At first glance, the task of managing thousands of miles of rail road track and keeping an eye on hundreds of units of rolling stock can seem particularly overwhelming. Fortunately, digital technology vastly simplifies this challenge by providing railroads with a means to remotely monitor train status and rail status from central administration centers, often located miles from the sites that they are monitoring.

In order to ensure safety and streamline the process of managing a huge, complicated rail system, modern railroad tracks are often lined with a series of small, wayside monitoring stations. In addition to monitoring rail traffic and switching status, these wayside stations can also be used to check track conditions, weather conditions and bridge safety as well as controlling track lubrication and other functions. Without these wayside monitoring stations, the task of managing a large rail system would require a veritable army of on-site personnel.

A typical wayside monitoring station might include sensors to monitor train speed, traffic levels, open/closed track switches and track wear conditions and icing, plus security cameras and other devices to ensure track security. The safety, security and monitoring functions provided by these wayside stations are so important, that when one or more of these stations are down, rail traffic often grinds to a halt until the problem can be corrected. Obviously, an efficient, reliable out-of-band management for these wayside stations is absolutely imperative.

Due to the remote nature of many of these wayside monitoring stations, a workable out-of-band management solution will typically rely on cellular broadband communication. When normal network communication is not available, remote administrators can communicate with the wayside monitoring station via 4G LTE cellular broadband in order to reboot unresponsive devices, power-on back-up equipment or access console port command functions on devices at the wayside station.

A 4G LTE cellular broadband based, out-of-band management solution enables administrators at distant control centers to instantly establish emergency contact with a wayside station in order to promptly restore monitoring capabilities, without shutting down the track or waiting for a service team to travel to the remote site. A WTI CPM-1600-1-ECA Console Server + PDU Hybrid equipped with the 4G LTE Cellular Option can provide remote, out-of-band console port access and power reboot functions for AC powered wayside stations, while the combination of a WTI RPC Remote DC Power switch working in tandem with a DSM-40DC-E Serial Console Server equipped with the 4G LTE Cellular Option can cover port access an power switching requirements in DC powered wayside station applications.

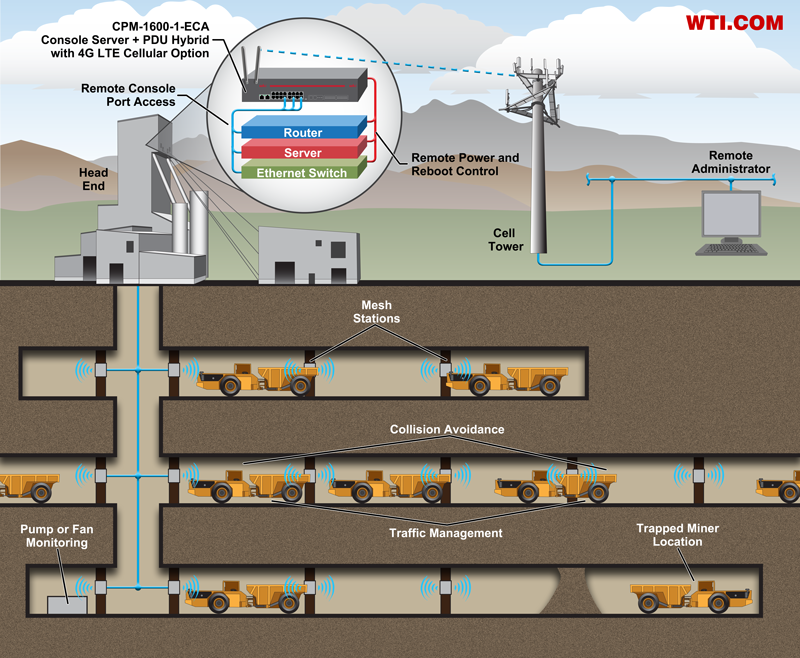

Managing Network Devices in Mining Applications

Reliable communications are a vital factor in large scale mining operations. In addition to helping to maximize productivity by limiting downtime and cutting the time required to solve unexpected problems below ground, an effective communications solution can also simplify the task of locating miners within the mine and provide for rapid notification of rescue personnel in the event of an emergency.

In most cases, mines employ wireless mesh technology to simplify VOIP communication below ground. Mesh technology provides an ideal fit for the communication needs of the mining industry, whereas more familiar communication technologies such as cellular broadband and wire phone lines are largely impractical when implemented inside the mine. Cellular signals generally can’t penetrate the mine’s dense rock walls and wire phone lines are expensive to install and maintain and also vulnerable to damage by mining equipment and fallen rocks. To add to the bargain, mesh technology also provides mobility and flexibility in an environment where work sites are constantly on the move, often relocating daily in order to follow a rich seam of ore or coal.

The layout of a mesh communication system is fairly simple; wireless mesh nodes are generally installed on support columns located throughout the mine and then linked to an above-ground, head end communication facility, which typically includes routers, servers and switches, similar to what would be seen in any large, corporate data center. In addition to allowing personnel within the mine to contact above-ground personnel, the head end communication facility will also offer some means (typically satellite network) to communicate with other mines belonging to the same company, plus allow communication with the corporate office.

Although this system generally works very well, there is one weak point. If a server or router located in the head end communication facility crashes, or if satellite communication suddenly fails, then all communication with the mine is dead until tech support can remedy the problem. Given the extremely remote location of most mining operations, it can take days for a tech team to travel from the home office to the mining site in order to restore communication. This sort of delay can result in hundreds of lost man-hours of productivity since many governments have regulations that require constant communication with below ground personnel, and when the mesh network is down, all productivity at the mine must be stopped.

Fortunately, there’s a relatively simple solution to this problem; in addition to primary communication via satellite, the head end facility should also include a secondary, 4G LTE cellular broadband based out-of-band communication strategy. When a cellular broadband based out-of-band management solution is deployed, network engineers at the corporate office can establish a connection with the head end facility via 4G LTE cellular when satellite communication is down. For larger head end network applications, a WTI CPM-1600-1-ECA Console Server + PDU Hybrid equipped with the 4G LTE Cellular Option can provide out-of-band access to both console port command functions and remote power and reboot switching for up to sixteen devices. For smaller head end network applications with less rack space, a WTI CPM-800-1-ECAM Console Server + PDU Hybrid equipped with the 4G LTE Cellular Option can be deployed to provide out-of-band console access and power and reboot control for up to eight networked devices at the remote site.

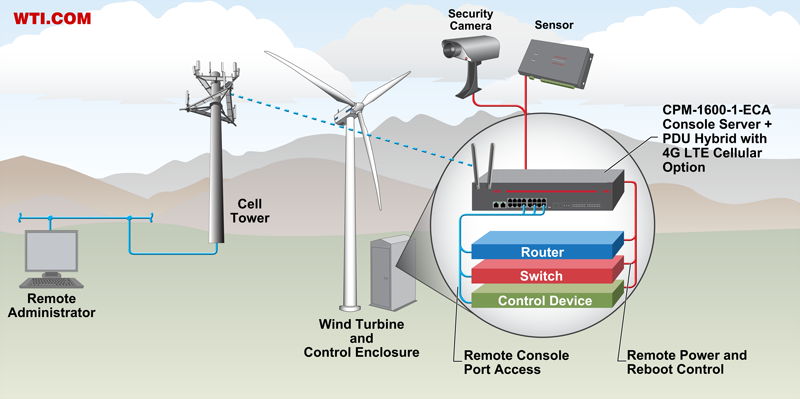

Managing Network Devices in Wind Turbine Towers

Wind turbine towers are a lot more complicated than they appear at first glance. In addition to generating power, wind turbines also include networked electronics such as servos that can be used to position turbine blades for maximum power generation, sensors to track wind speed and temperature, cameras and other security devices to ensure that the turbine is not tampered with and an assortment of other equipment, used to remotely manage each wind turbine tower.

In a typical wind farm implementation, servo motors, sensors and security devices in each wind turbine are linked to a network switch in the tower, which is in turn linked to the wind farm’s Ethernet backbone in order to allow remote towers to be easily managed from a central control facility.

Although this arrangement works well when functioning correctly, a simple network problem can often leave turbines unmanaged until the network can be brought back online again. Without a reliable out-of-band communication solution, technicians might have to visit many individual towers in order to reboot or reconfigure devices and bring the network back up again. In addition to wasting time and money, this situation can also result in damage to wind turbines if administrators at the central control facility are unable to slow or stop turbines that are either overheating, or being spun too rapidly by high winds.

A 4G LTE cellular broadband network can provide an economical, out-of-band back-up solution for network communication when wind farm networks crash or die. Cellular broadband lends itself well to the wind farm environment because it eliminates the need to run cables for a back-up hard-wired network, yet provides a reliable out-of-band means to access devices in remote wind turbine towers when the primary network is unavailable.

When a WTI CPM-1600-1-ECA Console Server + PDU Hybrid with the 4G LTE Cellular Option is installed at the wind turbine site, remote administrators can establish an out-of-band connection via cellular broad band in order to quickly access console port command functions and power reboot capabilities without the hassle and expense of travelling to the remote site to take care of the problem in person. If the wind turbine relies on DC powered sensors and servos, then a WTI RPC Series Remote DC Power Switch and a WTI DSM-40DC-E Serial Console Server with the 4G LTE Cellular Option can be used to access console ports and manage power and reboot switching at the remote site.

Includes Enterprise Management Software

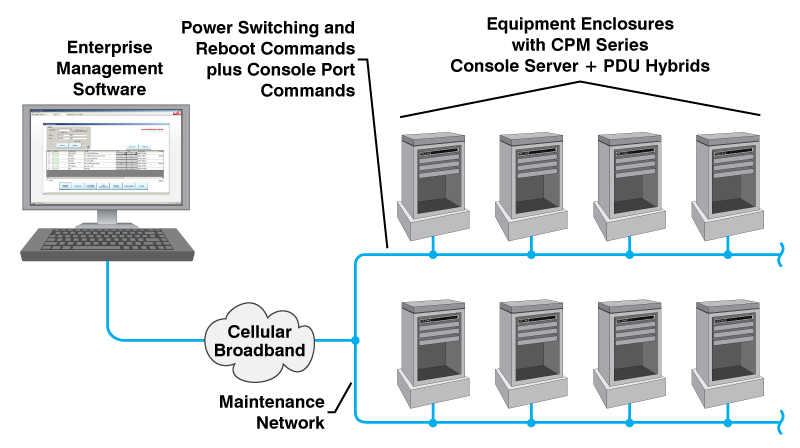

In order to simplify the task of managing multiple console servers and switched PDUs in large network applications, all WTI out-of-band management products include WMU Enterprise Management Software. WMU Enterprise Management Software provides administrators with a convenient centralized interface which can be used to locate and control specific WTI devices spread throughout your network infrastructure, drastically reducing the time required to find the desired device and implement power reboot or remote console access functions.

The Enterprise Management Software can search a user-defined IP address range on your network and discover all WTI devices within the range. Discovered units are then added to the Enterprise Management Software’s inventory, allowing administrators to assign descriptive tags to each out-of-band management device in order to denote the location or function of the device. In addition to providing a convenient interface for remote console port access and reboot control, the Enterprise Management Software can also be used to control firmware updates for WTI products and edit and manage user accounts at individual or multiple WTI devices.

In addition to the examples discussed in this article, there are also dozens of other industries and applications that can use a cellular broadband connection to a WTI console server or switched PDU to provide out-of-band access to remote network equipment when a normal network connection is not available or practical. As mentioned previously, in applications that require an alternative, out-of-band means to communicate with remote network devices cellular broadband and satellite communication are often the only alternatives available. While there are drawbacks to both cellular broadband and satellite based out-of-band management solutions, there are also distinct advantages that are peculiar to each method too. As is often the case, the out-of-band management solution that is eventually chosen will usually depend upon careful consideration of the specific needs, nature, budget and design of the application in question.

Request a free demo

WTI products can be demo'd through any of the following options: